Motors & Linear Actuators

1. Gear trains simply take input speed and torque and multiply or divide them depending on ratio. Some torque is lost due to friction, but the basic output performance mimics the input performance. just scaled up or down for ratio. Therefore the motor performance characteristics you see on this page will be the same characteristics you would see from a gearmotor.

1. Gear trains simply take input speed and torque and multiply or divide them depending on ratio. Some torque is lost due to friction, but the basic output performance mimics the input performance. just scaled up or down for ratio. Therefore the motor performance characteristics you see on this page will be the same characteristics you would see from a gearmotor.

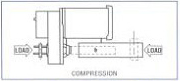

All of our linear actuators are intermittent duty rated. The thrust rating shown in the Data sheets are set up around 20% on-time per minute of operation. For infrequent bursts of power, most units can handle up to 1.25 times rated load. Consistent heavy cycling of loads in excess of the rating may cause units to fail. When in the design stage, keep in mind that although Adacel linear actuators are designed to provide equal thrust in both directions, the load bearing capacity is higher in compression than in tension.

All of our linear actuators are intermittent duty rated. The thrust rating shown in the Data sheets are set up around 20% on-time per minute of operation. For infrequent bursts of power, most units can handle up to 1.25 times rated load. Consistent heavy cycling of loads in excess of the rating may cause units to fail. When in the design stage, keep in mind that although Adacel linear actuators are designed to provide equal thrust in both directions, the load bearing capacity is higher in compression than in tension.Mounting and Alignment

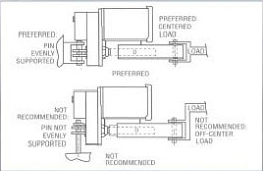

In order to get proper performance and maximum life, linear actuators should be mounted to be free of side loads. The best way to ensure this is to use clevis mounting at each end and to ensure that the clevis mounting pins remain parallel at all times.

In order to get proper performance and maximum life, linear actuators should be mounted to be free of side loads. The best way to ensure this is to use clevis mounting at each end and to ensure that the clevis mounting pins remain parallel at all times.Linear Actuator Wiring

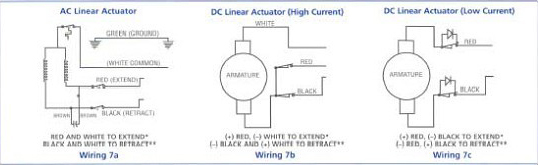

AC linear actuators come standard with PSC motors that have capacitors already mounted and wired in. DC linear actuators have two wiring diagrams depending on the amp draw of the motor. All units are prewired through limit switches that shut the actuator off at either end of stroke. (Wiring 7a,7b,7c)

AC linear actuators come standard with PSC motors that have capacitors already mounted and wired in. DC linear actuators have two wiring diagrams depending on the amp draw of the motor. All units are prewired through limit switches that shut the actuator off at either end of stroke. (Wiring 7a,7b,7c)

Torque Ratings vs. Duty Cycle

Torque Overhung Load

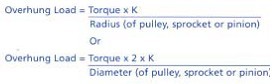

| If the gearmotor output shaft transmits its torque through a chain, pulley, gear train or rack and pinion, these devices will create an overhung load on the shaft. This load can be figured by the equation below. |

|

| K is a load factor for the type of transmission you use. For chain and sprocket. K=1.0;for belt and pulley. K=1.5. Be sure that your pulley. Sprocket or pinion diameter is large enough to stay within the published overhung load capacities. |

Bldg. 12 LianDa Industrial Zone, No.8 LuJia North Rd, LuDu Town, Tai Cang City, JiangSu, P.R.C. Postal Code.:215412 堊ICP姥05048877

Copyrights © 2013 Adacel Technologies , LTD All Rights Reserved.

Tel: 86-512-8275-7188 Fax: 86-512-8275-7189 email:info@adaceltech.com vl@adaceltech.com jenny@adaceltech.com